Wide selection of Materials and Coatings to meet the most demanding applications

Materials:

- Inconel 718

- Alloy X-750

- Waspaloy

- Cres 304

- Elgiloy

- Haynes 282

- Hasteloy

- Rene 41

Building Trust and Reliability: Manufacturing Resilient Metal Seals for Small Nuclear Reactors and Micro Modular Reactors

Much like a commercial airliner’s transatlantic journey, where trust and precision are paramount due to the absence of runways and zero margin for error, nuclear fusion secures its success through the critical role of resilient metal seals. Small nuclear reactors (SMRs) and micro modular reactors (MMRs) depend on these seals to ensure safe and efficient operation. At JETSEAL, we understand the extensive importance of radiation resistant sealing materials in these advanced nuclear applications. Our commitment lies in providing high-quality nuclear sealing solutions that guarantee safety, efficiency, and optimal performance. With scientific expertise, cutting-edge technology, and meticulous quality control, we deliver metal seals that are tested and trusted worldwide for the success of SMRs and MMRs.

As the world seeks to advance towards the next generation of nuclear energy, Generation IV reactors hold immense promise in terms of safety, efficiency, and sustainability. Resilient metal seals play a pivotal role in ensuring the reliable and safe operation of these advanced reactor designs. At JETSEAL, we understand the criticality of metal seals in Generation IV reactors and are dedicated to manufacturing high-quality seals that optimize their performance. With our focus on innovation, expertise, and stringent quality control, we contribute to the progression of Generation IV reactor technology by delivering reliable metal seals tailored specifically for these reactors.

As the world seeks to advance towards the next generation of nuclear energy, Generation IV reactors hold immense promise in terms of safety, efficiency, and sustainability. Resilient Metal seals play a pivotal role in ensuring the reliable and safe operation of these advanced reactor designs. At JETSEAL, we understand the criticality of metal seals in Generation IV reactors and are dedicated to manufacturing high-quality seals that optimize their performance. With our focus on innovation, expertise, and stringent quality control, we contribute to the progression of Generation IV reactor technology by delivering reliable metal seals tailored specifically for these reactors.

Gas-cooled Fast Reactor (FR)

Lead-cooled Fast Reactor (LFR)

Molten Salt Reactor (MSR)

Supercritical Water-cooled Reactor (SCWR)

Sodium-cooled Fast Reactor (SFR)

Very High Temperature Reactor (VHTR)

Metal seals are typically made of high-quality materials such as 316L stainless steel, which offers excellent corrosion resistance, high-temperature stability, and compatibility with fusion plasma environments. These materials ensure the longevity and reliability of metal seals in extreme operating conditions.

Metal seals work by creating a reliable barrier between different components within a fusion reactor. They utilize precise engineering and manufacturing techniques to ensure a tight and secure connection, preventing leakage and maintaining the integrity of the reactor’s containment system. Metal seals are designed to withstand extreme temperatures, high pressures, and harsh operating conditions, providing reliable containment and optimal performance.

Metal seals are specialized components used in nuclear fusion reactors to ensure reliable containment and prevent leakage. They are precision-engineered and manufactured to create a secure barrier between different parts of the reactor, effectively sealing off critical areas and maintaining the integrity of the reactor’s containment system.

Metal-to-metal sealing refers to a sealing mechanism where two metal surfaces come into direct contact with each other to create a reliable seal. This type of sealing ensures a tight connection and is often used in applications that require high-pressure containment, such as nuclear fusion reactors. Metal-to-metal seals offer enhanced reliability and durability in demanding operating conditions.

Why Resilient Metal Seals Should Not Be Reused in Nuclear Applications

For nuclear design engineers worldwide, the choice of components is crucial. Among these, resilient metal seals have become a staple in sealing solutions. However, when it comes to their reuse in nuclear applications, there are extensive reasons to reconsider:

In conclusion, for nuclear design engineers aiming to secure the best solutions, it’s essential to avoid the reuse of resilient metal seals in nuclear applications. The risks far outweigh the benefits, and the safety and integrity of nuclear operations should always be paramount.

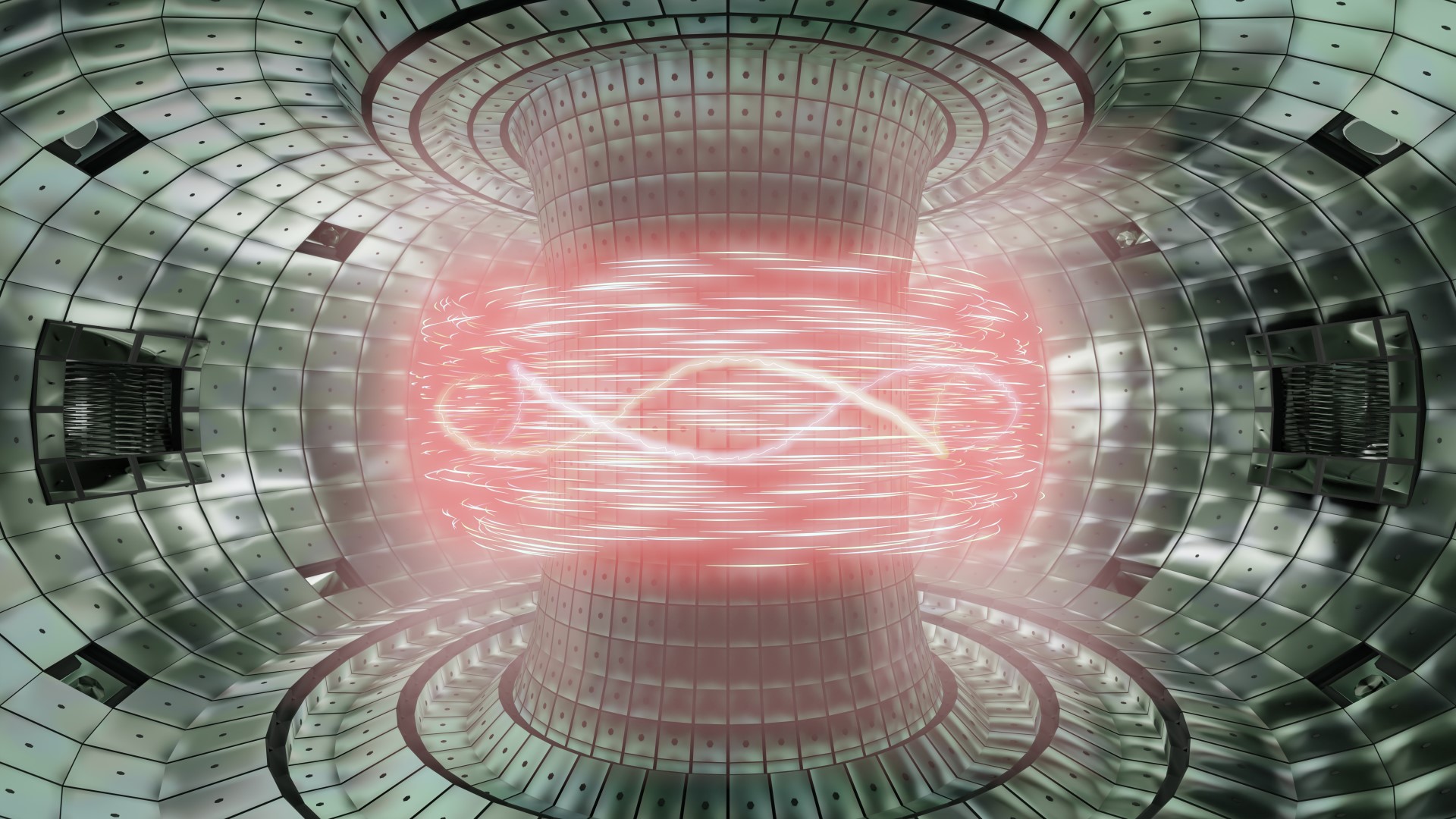

While significant progress has been made in fusion research, the development of commercial fusion power is still undergoing extensive research and development. Scientists and engineers are continually working towards achieving the three essential conditions for nuclear fusion: high temperature, high pressure, and sufficient confinement time. Once these conditions are met consistently and sustainably, fusion power can become a reality.

The three conditions needed for nuclear fusion are high temperature, high pressure, and sufficient confinement time. These conditions are necessary to achieve the fusion of atomic nuclei and release energy. In fusion reactors, such as Tokamak reactors, these conditions are meticulously controlled and optimized to create the ideal environment for sustained fusion reactions.

A fusion reactor avoids melting through careful design and control of the operating conditions. The reactor is engineered with materials that can withstand the high temperatures generated by fusion reactions. Additionally, precise cooling mechanisms and advanced thermal management techniques are employed to remove excess heat and maintain the reactor’s structural integrity.

One of the main challenges of fusion is achieving a self-sustaining reaction, where the energy output exceeds the energy input. This is often referred to as achieving net energy gain. While significant progress has been made, the attainment of net energy gain on a commercial scale remains a significant technical challenge in fusion research and development.

Yes, Generation IV reactors refer to a set of advanced nuclear reactor designs that have been under development worldwide. These reactors aim to address key challenges in current nuclear technology and offer improved safety, efficiency, and sustainability. Examples of Generation IV reactor designs include sodium-cooled fast reactors (SFRs), gas-cooled fast reactors (GFRs), and molten salt reactors (MSRs), among others. Metal seals play a critical role in ensuring the reliable operation of these advanced reactor systems.

Cladding in a nuclear reactor refers to the protective material that surrounds the fuel rods, providing a barrier between the nuclear fuel and the reactor coolant. The cladding material used in nuclear reactors is typically made of zirconium alloys. Metal seals, along with other components, help ensure the integrity and containment of the cladding, preventing leaks and maintaining the safety and efficiency of the reactor.

The Generation IV designs are guided by several key principles, including enhanced safety, sustainability, and improved performance. These designs aim to develop reactors with enhanced inherent safety features, reduced waste generation, improved fuel utilization, and increased thermal efficiency. Metal seals, as critical components in Generation IV reactors, contribute to these guiding principles by ensuring reliable containment, preventing leaks, and facilitating efficient operation, ultimately enhancing safety and performance.

Molten salt reactors pose several challenges due to the corrosive nature of the high-temperature liquid fuel and the potential for radioactive material release. However, with the implementation of high-quality metal seals, such as those provided by JETSEAL. By partnering with JETSEAL, these challenges can be managed. Metal seals act as reliable barriers, preventing leaks and maintaining the integrity of critical components and fuel containment systems within the molten salt reactor, thereby enhancing safety and operational efficiency.

One of the disadvantages of sodium fast reactors lies in the reactivity of sodium with air and water, which can lead to potentially hazardous situations if not properly managed. Metal seals, specifically designed for sodium fast reactors, play a crucial role in containing and isolating the liquid sodium coolant, minimizing the risk of leaks and ensuring the safe operation of the reactor.

Molten-salt reactors require materials that can withstand the extreme temperatures and corrosive nature of the fuel. At JETSEAL, we offer a wide range of materials suitable for molten-salt reactor applications, including high-temperature alloys, corrosion-resistant metals, and specialized coatings. These materials are carefully selected to ensure compatibility with molten salt environments, providing robust and durable sealing solutions.

Drawbacks of molten salt reactors include challenges related to the management of radioactive materials, the corrosion of structural materials, and the potential for fuel leakage. However, by employing high-quality metal seals specifically designed for molten salt reactor applications, these drawbacks can be addressed effectively. Metal seals provided by JETSEAL contribute to the containment of radioactive materials, prevent leaks, and ensure the integrity of critical components, enhancing the overall safety and reliability of molten salt reactors.

Embarking on the path of advanced nuclear energy, sodium fast molten salt reactors (SFRs) have emerged as formidable contenders, harnessing the power of liquid fuel and efficient heat transfer. Within this realm, metal seals play a vital role in guaranteeing the performance, reliability, and safety of SFRs. At JETSEAL, we understand the criticality of metal seals in sodium fast molten salt reactors and remain committed to manufacturing engineered seals that optimize their operation. With an unwavering focus on innovative solutions, specialized expertise, and uncompromising quality control, we actively contribute to the advancement of SFR technology by delivering impeccable metal seals specifically tailored for these reactors.

Molten salt reactors pose several challenges due to the corrosive nature of the high-temperature liquid fuel and the potential for radioactive material release. However, with the implementation of high-quality metal seals, such as those provided by JETSEAL. By partnering with JETSEAL, these challenges can be managed. Metal seals act as reliable barriers, preventing leaks and maintaining the integrity of critical components and fuel containment systems within the molten salt reactor, thereby enhancing safety and operational efficiency.

One of the disadvantages of sodium fast reactors lies in the reactivity of sodium with air and water, which can lead to potentially hazardous situations if not properly managed. Metal seals, specifically designed for sodium fast reactors, play a crucial role in containing and isolating the liquid sodium coolant, minimizing the risk of leaks and ensuring the safe operation of the reactor.

Molten-salt reactors require materials that can withstand the extreme temperatures and corrosive nature of the fuel. At JETSEAL, we offer a wide range of materials suitable for molten-salt reactor applications, including high-temperature alloys, corrosion-resistant metals, and specialized coatings. These materials are carefully selected to ensure compatibility with molten salt environments, providing robust and durable sealing solutions.

Drawbacks of molten salt reactors include challenges related to the management of radioactive materials, the corrosion of structural materials, and the potential for fuel leakage. However, by employing high-quality metal seals specifically designed for molten salt reactor applications, these drawbacks can be addressed effectively. Metal seals provided by JETSEAL contribute to the containment of radioactive materials, prevent leaks, and ensure the integrity of critical components, enhancing the overall safety and reliability of molten salt reactors.

The three conditions needed for nuclear fusion are high temperature, high pressure, and sufficient confinement time. These conditions are necessary to achieve the fusion of atomic nuclei and release energy. In fusion reactors, such as Tokamak reactors, these conditions are meticulously controlled and optimized to create the ideal environment for sustained fusion reactions.

Resilient Nuclear Metal Seals play a pivotal role in the performance of Tokamak nuclear fusion reactors, serving as the guardians of containment in an environment that demands absolute trust and precision. At JETSEAL, we deeply recognize the criticality of Nuclear Metal Seals in Tokamak fusion reactors. Our dedicated focus is on manufacturing high-quality seals that optimize performance, reliability, and safety. With exceptional capabilities in producing Nuclear Metal Seals for nuclear fusion reactors, we surpass industry standards by combining innovation, expertise, and stringent quality control. Our mission is to deliver products that enable the advancement of clean and sustainable energy solution.

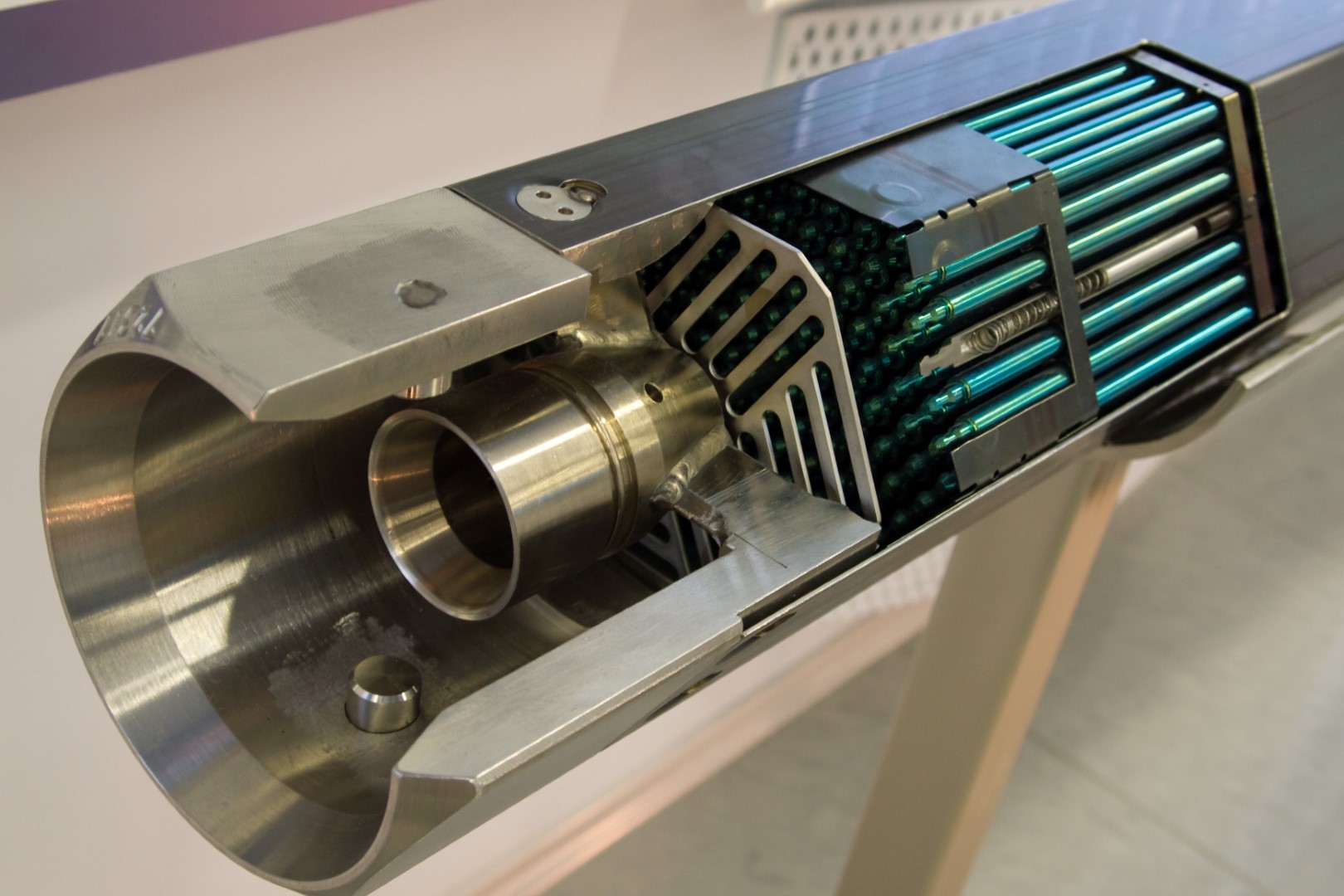

The U-Mega Seal represents a breakthrough in sealing technology, combining the load performance of the Omega Seal with the exceptional sealing characteristics of the C-Seal. This innovative design achieves the highest level of reliability while maintaining an extremely low leakage rate, making it an ideal choice for critical nuclear applications.

One of the key advantages of the U-Mega Seal is its simplified installation. Unlike the Omega Seal, the U-Mega Seal does not require any special machining or lapping at the edge to meet the flatness requirements. Instead, the seal lip is turned inward, harnessing the proven performance of the C-Seal. This design feature streamlines the installation process and ensures consistent and reliable sealing performance.

Operating within demanding nuclear environments, the U-Mega Seal demonstrates impressive capabilities:

Operating Pressure Range: The U-Mega Seal can operate effectively in a wide pressure range, from vacuum conditions as low as 1E-10 torr. up to an impressive 36,000 psi. This versatility enables its use in various nuclear reactor systems, accommodating diverse operational requirements.

Functional Temperature Range: With a functional temperature range spanning from cryogenic conditions to as high as 1350°F (732°C), the U-Mega Seal exhibits remarkable thermal stability. It is engineered to withstand extreme temperature differentials, ensuring reliable sealing performance even in the harshest nuclear environments.

Exceptionally Low Leakage Rate: The U-Mega Seal boasts an industry-leading typical leakage rate of 1E-10 sccs He/mm circ. This exceptional level of sealing efficiency guarantees the integrity and safety of nuclear systems by preventing the escape of hazardous materials and minimizing environmental impact.

– Alloy 718 (AMS 5596, 5589, 5662)

– Alloy X-750 (AMS 5598, 5582, 5667)

– Waspaloy (AMS 5544, 5706, 5586, 5708)

– Silver (AMS 2410, 2411)

– Nickel (AMS 2403, 2424, QQ-N-290)

– Gold (Mil-G-45204)

When it comes to reliability, low leakage, and performance in nuclear applications, the U-Mega Seal sets a new standard. Trust this cutting-edge sealing solution to enhance the safety and efficiency of your nuclear systems, ensuring the integrity of your operations.

When searching for reliable metal seal solutions for nuclear reactors, trust the U-Mega Seal to meet your needs. With its exceptional leakage control, high compression strength, and outstanding pressure resistance, the U-Mega Seal provides the ultimate sealing performance for nuclear engineers. Enhance the safety and efficiency of your nuclear energy systems with the U-Mega Seal, the preferred choice for sealing in demanding nuclear environments.

For more information or to discuss how the U-Mega Seal can address your specific needs, please do not hesitate to reach out. Our team of experts is ready to assist you in optimizing your sealing solutions for the challenges of the nuclear industry.

JETSEAL takes pride in offering C-Seals that are specifically designed for nuclear sealing applications. Our C-Seals are not only of superior quality but also provide cost-effective solutions tailored to meet the unique challenges of the nuclear industry. With versatile configurations and the ability to customize the diameter and material, our C-Seals are an ideal choice for achieving reliable sealing in nuclear environments.

We adhere to the highest standards of quality in manufacturing C-Seals, ensuring that all critical features are closely controlled to consistently deliver optimum performance. To guarantee excellent sealing performance, the sealing surfaces of our C-Seals undergo a proprietary polishing process developed by JETSEAL. This innovative approach ensures continuous sealing contact, providing exceptional performance in both standard cavities and scenarios involving dynamic separation, which are common in nuclear applications.

Operating within demanding nuclear environments, JETSEAL C-Seals excel in the following conditions:

Operating Pressure Range: Our C-Seals are designed to operate effectively across a wide pressure range, from vacuum conditions as low as 1E-10 torr. up to an impressive 60,000 psi. This exceptional pressure capability makes them well-suited for sealing critical components within nuclear reactors and systems.

Functional Temperature Range: With a functional temperature range spanning from cryogenic conditions to as high as 1400°F (760°C), our C-Seals exhibit remarkable thermal stability. They are engineered to withstand the extreme temperature differentials commonly encountered in nuclear applications, ensuring reliable sealing performance in challenging operating conditions.

Typical Leakage Rate: JETSEAL C-Seals boast a typical leakage rate as low as 1E-8 sccs He/mm circ., ensuring minimal leakage and enhancing the integrity and safety of nuclear systems. This exceptional sealing efficiency contributes to the prevention of radioactive material leakage, protecting personnel and the environment.

When it comes to nuclear sealing applications, JETSEAL C-Seals offer exceptional quality, customization, and performance. Trust our reliable sealing solutions to meet the stringent requirements of the nuclear industry and ensure the safety and efficiency of your nuclear systems

When searching for reliable metal seal solutions for nuclear reactors, trust JETSEAL Metal C-Seals to meet your needs. With their exceptional leakage control, high compression strength, and outstanding pressure resistance, Metal C-Rings provide the ultimate sealing performance for nuclear engineers. Enhance the safety and efficiency of your nuclear energy systems with Metal C-Rings, the preferred choice for sealing in demanding nuclear environments.

For further assistance or to discuss how JETSEAL C-Seals can address your specific nuclear sealing needs, please do not hesitate to contact us. Our experienced team is ready to provide tailored solutions and expert support for your nuclear sealing projects.

Wide selection of Materials and Coatings to meet the most demanding applications

Materials: