- Hot sections such as nozzles and segment assembly

- Semi-dynamic sealing solutions for inlet or outlet ducting

- Production parts such as c-seal, E-seals, omega seals, or JETSEAL’s proprietary Lever Seal profiles.

- Designed, engineered, and manufactured to your applications specifications

- Capable of extremely low leak rates in extreme temperatures

- Endures corrosive environments

- Custom Design and Build per customer spec or in co-development with our Engineering Team

- Precision Manufacturing and Stringent Quality Controls

- Testing, Testing and more Testing

- Complimentary FEA support

Providing solutions

of every kind,

start to end

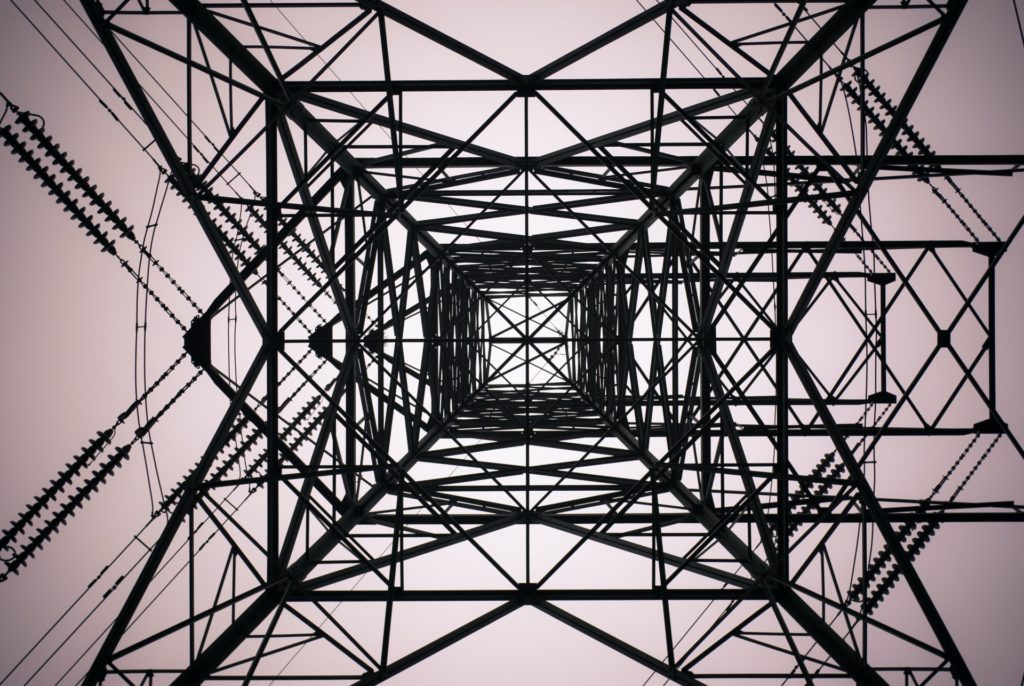

Power generation equipment manufacturers rely on JETSEAL’s resilient metal seals to increase the efficiency and longevity of their products.